Hydronic industrial unit heaters, powered by hot water and either gas or electricity, offer efficient heating for warehouses and manufacturing facilities. Suspended heaters provide uniform warmth, while forced air systems enhance circulation. These versatile systems, with customizable BTU ratings, ensure energy efficiency, cost savings, and low maintenance in diverse industrial settings. Regular maintenance is key to optimal performance.

“Explore the realm of efficient heating with hydronic industrial unit heaters, a game-changer in modern manufacturing. This comprehensive guide delves into the inner workings of these advanced systems, powered by hot water. Discover how this innovative technology offers unparalleled benefits, from precise temperature control to enhanced energy efficiency. We’ll uncover applications across various industries and provide insights on maintenance, ensuring optimal performance. By understanding hydronic heaters, businesses can revolutionize their processes.”

- Understanding Hydronic Industrial Unit Heaters

- How Hot Water Heating Systems Work

- Benefits of Hot Water for Industrial Heating

- Applications and Industries Served

- Maintenance and Efficiency Considerations

Understanding Hydronic Industrial Unit Heaters

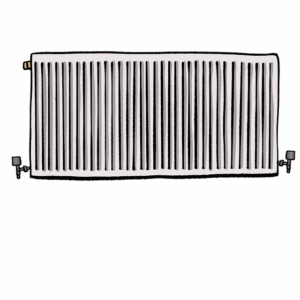

Hydronic industrial unit heaters are advanced heating systems designed for heavy-duty construction and demanding industrial applications. Unlike traditional forced air heating methods, hydronic systems utilise hot water to transfer heat, offering several advantages in warehouse heating and manufacturing facilities. This approach not only ensures efficient temperature control but also provides better energy distribution, making it ideal for large commercial heating needs.

These heaters come in various types, including suspended heaters and electric unit heaters, each tailored to specific requirements. The choice between gas fired heaters and electric models depends on factors such as available energy sources, cost efficiency, and desired BTU ratings. With their versatility and ability to withstand harsh environments, hydronic industrial unit heaters are a popular choice for maintaining comfortable and safe temperatures in diverse industrial settings.

How Hot Water Heating Systems Work

Hydronic industrial unit heaters utilize hot water to efficiently heat large spaces in manufacturing facilities and warehouses. Unlike gas fired heaters or electric unit heaters, hydronic systems distribute heat through suspended heaters, enabling uniform warmth across heavy duty construction settings. This method of commercial heating is particularly advantageous for industrial applications that demand consistent temperatures.

The process begins with a central boiler generating hot water, which is then pumped through pipes installed throughout the facility. These pipes are typically nestled within floors or walls, ensuring optimal heat transfer. Forced air heating systems can be integrated to enhance circulation and reach every corner, making it ideal for spaces with high ceilings or unusual layouts. Each suspended heater is carefully calibrated, and its BTU ratings ensure efficient heating based on the area’s size and specific heat requirements, thereby optimizing energy use in industrial environments.

Benefits of Hot Water for Industrial Heating

Hydronic industrial unit heaters that utilize hot water for heating offer several significant advantages in various industrial settings, including warehouses and manufacturing facilities. Unlike gas fired heaters or electric unit heaters, hot water systems are designed for heavy duty construction and can efficiently distribute heat across vast commercial spaces. This makes them ideal for industrial applications that demand consistent and reliable temperature control.

One key benefit is their ability to provide forced air heating with superior BTU ratings, ensuring quick and even heating throughout the entire space. The use of hot water also offers energy efficiency and cost savings compared to traditional electric heaters or suspended heaters. Additionally, these systems are known for their durability and low maintenance requirements, making them a reliable choice for long-term warehouse heating and other demanding industrial applications.

Applications and Industries Served

Hydronic industrial unit heaters are versatile and find applications across a wide range of industries, offering efficient and effective solutions for warehouse heating and manufacturing facilities. Their ability to provide consistent heat makes them ideal for heavy duty construction sites and other demanding industrial applications. These heaters can be tailored to meet specific requirements, with options such as gas fired heaters or electric unit heaters, ensuring optimal performance in various environments.

Suspended heaters, for instance, are popular in commercial heating due to their flexibility and ease of installation. Forced air heating systems, too, offer advantages like quick response times and precise temperature control, catering to the diverse needs of modern industrial processes. Each heater is designed with specific BTU ratings to deliver the required thermal output, ensuring comfort and efficiency in settings ranging from vast manufacturing floors to outdoor storage areas.

Maintenance and Efficiency Considerations

Proper maintenance is key to keeping hydronic industrial unit heaters running efficiently and effectively. Regular cleaning and inspection of the heating system, including water treatment and filter changes, are essential to prevent buildup and ensure optimal performance. Additionally, monitoring BTU ratings and comparing them against actual usage can help identify potential inefficiencies, allowing for timely adjustments to maintain peak operating conditions.

In industrial applications like warehouses and manufacturing facilities, where heavy-duty construction and forced air heating are common, integrating gas fired heaters or electric unit heaters with suspended heaters can offer enhanced flexibility and control over temperature regulation. This combination caters to diverse space requirements and specific heating needs, contributing to a more energy-efficient and cost-effective commercial heating solution.

Hydronic industrial unit heaters, powered by hot water, offer a robust and efficient heating solution across various industries. By leveraging hot water for heating, these systems provide numerous benefits, including enhanced energy efficiency, improved safety, and reduced environmental impact. With their versatility and reliability, hydronic industrial unit heaters are the go-to choice for maintaining optimal temperatures in diverse applications, ensuring processes run smoothly and productively. For businesses seeking a reliable and sustainable heating option, investing in hot water-based industrial unit heaters is a strategic decision that can drive success in today’s competitive market.