Maintaining comfortable temperatures in large industrial spaces with high ceilings requires specialized heating solutions like suspended heaters or forced air systems. Industrial unit heaters, designed for these applications, have high BTU ratings and robust construction to handle demanding commercial needs in warehouses and manufacturing facilities. Types include gas fired, electric, and suspended heaters, each optimized for specific requirements while ensuring efficient heat distribution through strategic installation and regular maintenance.

In many industrial spaces, high ceilings present unique heating challenges. This article delves into the specific needs and solutions for effectively warming large, expansive areas. We explore key features of efficient industrial unit heaters designed for high ceiling applications, discuss various types and their uses, and provide best practices for installation and maintenance. Understanding these aspects ensures optimal performance and energy efficiency in industrial environments.

- Understanding High Ceiling Challenges in Industrial Spaces

- Key Features of Efficient Unit Heaters for High Ceilings

- Types and Applications of Industrial Unit Heaters

- Best Practices for Installing and Maintaining High-Ceiling Heaters

Understanding High Ceiling Challenges in Industrial Spaces

In industrial spaces with high ceilings, unique challenges arise when it comes to maintaining optimal temperatures. These vast, open areas, often found in warehouses and manufacturing facilities, require efficient heating solutions tailored to their specific needs. Traditional heating methods might not suffice due to the increased vertical space, leading to a demand for specialized equipment.

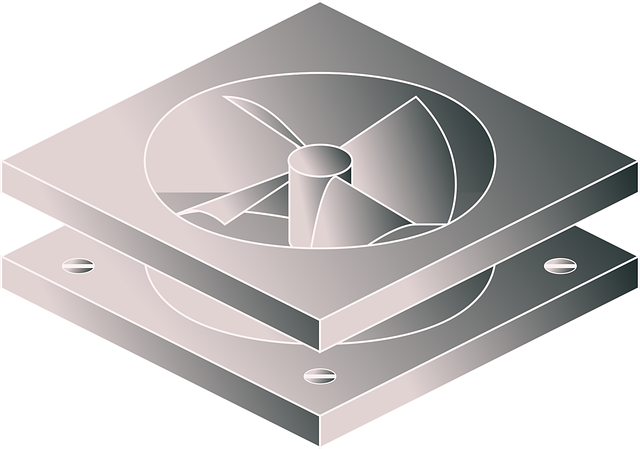

Industrial unit heaters designed for high ceiling applications must address these issues head-on. Features such as suspended heaters or forced air heating systems can effectively distribute warmth throughout the entire volume of the warehouse or factory. When selecting an industrial heater, BTU ratings become crucial in determining the capacity required to heat a given area. The heavy-duty construction of these heaters ensures they can withstand the demanding environments of commercial heating in various industrial applications.

Key Features of Efficient Unit Heaters for High Ceilings

Industrial unit heaters designed for high ceiling applications are a specialized subset within the larger category of commercial heating solutions. Key features distinguish them from standard models, ensuring optimal performance in large, open spaces like warehouses and manufacturing facilities. First and foremost, these heaters often incorporate heavy-duty construction to withstand the demands of industrial environments.

Suspended heaters, for instance, offer efficient forced air heating by hanging strategically above the desired area, distributing heat evenly across vast interiors. Gas fired heaters are a popular choice due to their high BTU ratings, providing rapid and robust warming. Alternatively, electric unit heaters excel in areas where gas access is limited, offering reliable and safe operation. Regardless of fuel type, these industrial heaters are engineered for durability, ensuring they can operate seamlessly in the toughest conditions, catering to the specific needs of various heavy-duty construction and industrial applications.

Types and Applications of Industrial Unit Heaters

Industrial unit heaters are versatile heating solutions designed to cater to a wide range of commercial and industrial applications, particularly in warehouse heating and manufacturing facilities. These heaters come in various types, each suited for specific needs. One popular choice is gas fired heaters, known for their efficiency and ability to quickly heat large spaces. They are ideal for outdoor or well-ventilated indoor areas, offering a cost-effective solution for industrial applications.

Another common type is electric unit heaters, favored for their ease of installation and operation. These heaters utilize forced air heating systems, circulates warm air evenly throughout the space, ensuring optimal comfort. With different BTU ratings available, they are suitable for a multitude of heavy duty construction sites and commercial heating requirements. Suspended heaters are also worth mentioning, offering discreet yet powerful heating solutions for high ceiling areas, making them perfect for modern industrial aesthetics.

Best Practices for Installing and Maintaining High-Ceiling Heaters

When installing industrial unit heaters designed for high ceiling applications, such as in warehouses or manufacturing facilities, adhering to best practices is paramount to ensure optimal performance and longevity. Firstly, assess the specific heating requirements based on factors like ceiling height, floor area, and insulation levels. This helps in selecting the appropriate BTU ratings for electric unit heaters or gas fired heaters, catering to both commercial heating needs and heavy duty construction environments.

Proper installation involves strategic placement of suspended heaters, particularly in industrial applications, to evenly distribute heat throughout the space. Utilize forced air heating systems where necessary to enhance circulation, ensuring every corner receives adequate warmth. Regular maintenance is another critical aspect; cleaning or replacing filters promptly, checking for any leaks, and scheduling professional inspections at set intervals will keep your high-ceiling heaters running efficiently.

Industrial unit heaters are essential for addressing the unique challenges posed by high ceiling applications. By understanding the specific needs of these spaces, choosing efficient models with advanced features, and implementing best practices during installation and maintenance, businesses can ensure optimal heating performance and energy savings. This tailored approach enhances comfort and productivity while extending the lifespan of industrial facilities.